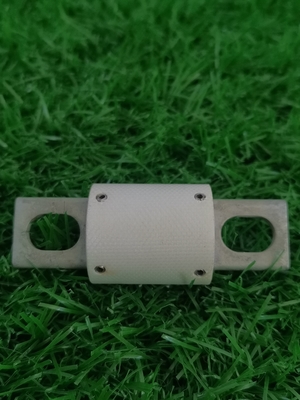

New Energy Automobile Fuse High Voltage Fuse EV Pack Fuse

1.Product Basic Information:

(1)EV-A-Q Series Fuses, Dimension and performance conform to UL248,GB13539,IEC60269,GB31465

(2)Rated Voltage: 250VDC, Rated Current: 400A, Breaking capacity: DC20KA

(3)Executive standard: Comply with UL248,GB13539,IEC60269,GB31465.

(4)This series products EV-A-Q are Ceramic Round Tube Bolted Fuses; Applicable for road vehicle. with small size, High Breaking capacity, Temperature shock resistance,Current surge, Mechanical vibration and shock, and Strong chemical load. Applicable for electric vehicle drive power system,Energy storage and power batteries,Energy storage capacitor,Frequency conversion controller,charger, wire and other automotive parts and equipment’s short circuit, overload and backup protection.

2.Product Characteristic:

| Model | Rated Current (A) | Installation |

| EV-A-Q-400 | 400 | Install Bolt M8, Recommend Torque: 11N.m |

3.M8 Bolted EV Fuse Materials:

| Part | Material |

| Fuse wire | Copper or Silver |

| End cap | Copper alloy tin plating |

| Fuse leg | Copper alloy tin plating |

| Fuse body | Ceramic Tube |

| Filler | Quartz sand |

4.Storage temperature:

EV Fuse Products storage temperature: -40°C ~ 105°C. The relative humidity is not more than 70% when 40°C. The relative humidity is not more than 80% when 30°C. The relative humidity is not more than 90% below 20°C.

Packaging storage temperature: -40°C ~ 70°C. The relative humidity is not more than 40% when 40°C. The relative humidity is not more than 50% when 30°C. The relative humidity is not more than 90% below 20°C, no condensation.

Fuses can be stored for average 1 year when the relative humidity ≦75%.

Not in the open air, fuses can be stored at most 30 days when the relative humidity 95%.

5.Mechanical features

5.1 copper cap

The copper cap should be firmly riveted to ensure that the copper cap cannot be removed when the fuse link is not damaged. After the sample is immersed in water at 15℃-35℃ for 24 hours and taken out, on each end cap, evenly apply a pulling force to 5N, keep it for 1 minute, the copper cap should not fall off.

5.2 Tensile test

One end copper cap fixing the fuse, then on the other end of the copper cap, apply a tension of 100N along the horizontal axis, The copper caps at both ends should not be loose and the pipe body should not be broken.

5.3 Tube strength test

After fixing the copper caps at both ends, apply a pressure of 200N to the center of the ceramic tube, the tube should not be broken.

6.Electric Vehicle Fuse Product Dimension:

Product equipment:

Test equipment:

Certificate:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!